This article describes the creation of a stunning silver mechatronic beetle necklace using 3D printing and investment casting techniques. The project was developed by Allie Katz and DJ Harrigan during a Formlabs-hosted hackathon, where they had access to specialized tools and expertise. The necklace features a silver beetle with LED lights and moving parts that respond to heat. It combines flexible and casting resins to achieve the desired texture and finish. The final piece is a unique blend of art and technology, showcasing the potential of 3D printing in jewelry design. This tutorial is worth reading because it highlights innovative methods for creating intricate metal objects. Readers will learn how to use 3D printing and investment casting to build a complex, interactive jewelry piece.

Key facts

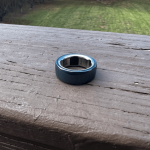

- The necklace was created using 3D printing and investment casting techniques.

- Allie Katz and DJ Harrigan developed the project during a Formlabs-hosted hackathon.

- The design includes a silver beetle with LED lights and moving parts that react to heat.

- Flexible resin was used for the leaves, while casting resin was used for the silver parts.

- The project showcases the potential of 3D printing in creating intricate and interactive jewelry.