Source of this article and featured image is DZone AI/ML. Description and key fact are generated by Codevision AI system.

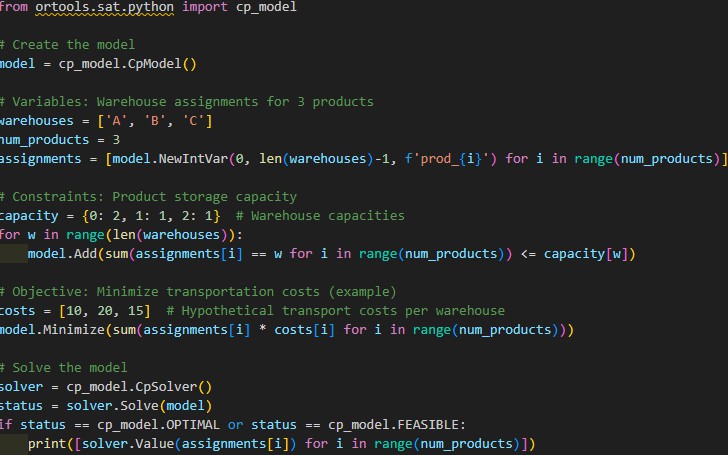

This article explores how AI-driven constraint programming is transforming supply chain management by combining machine learning with optimization techniques to create adaptive systems. Traditional methods struggle with dynamic environments, but AI enables real-time adjustments and resilience against disruptions. Shrinivas Jagtap explains how deep learning models dynamically adjust constraints using historical demand data for real-time decision-making. The tutorial includes practical examples like Walmart’s inventory optimization and Python code for warehouse allocation models. Readers will gain insights into implementing AI-based solutions for complex supply chain challenges.

Key facts

- AI-driven constraint programming merges machine learning with optimization to handle dynamic supply chain complexities.

- Deep learning models dynamically adjust constraints using historical demand data for real-time decision-making.

- Walmart improved seasonal demand forecasts by 40% and reduced stockouts by 30% through AI integration.

- The approach enables real-time logistics routing considering weather, fuel costs, and road conditions.

- Challenges include computational demands and data accuracy requirements for multi-echelon supply chains.

TAGS:

#AI in Supply Chain #constraint programming #Deep Learning Applications #inventory management #Logistics Optimization #machine learning #Python Code Examples #real-time analytics #supply chain optimization #Walmart Case Study